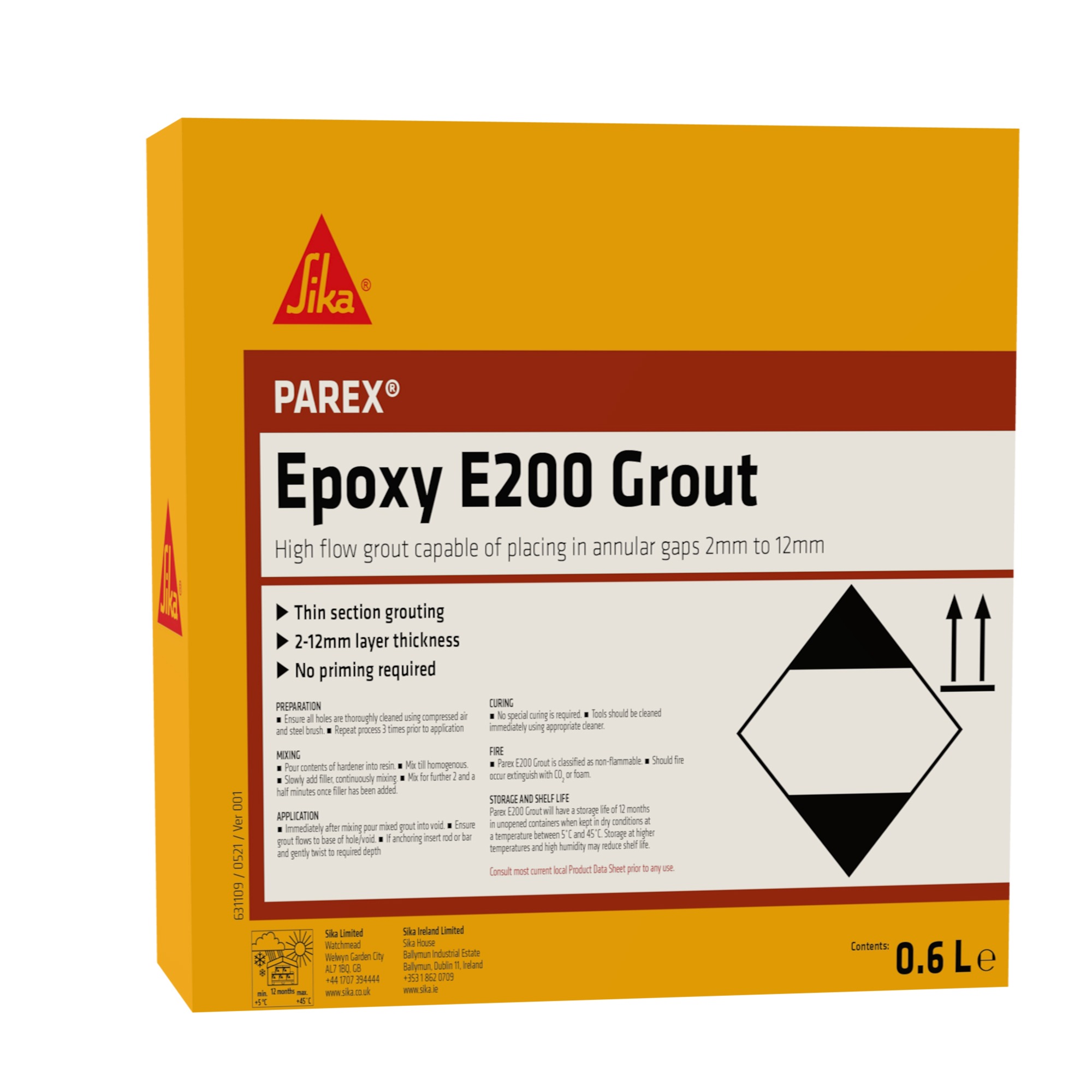

Parex E20 Epoxy Grout

Parex E20 Epoxy Grout is an epoxy resin based grout with high flow properties capable of placing in nominally parallel gaps down to 8mm. Tapered gaps may be filled down to a featheredge. The epoxy resin formulation enables E20 Epoxy Grout to be used in the most demanding situations giving exceptional mechanical strength. The volume stable mix design ensures complete fill of the grouted area and contact with the work piece.

The three part formulation gives good chemical resistance to most chemicals. Stable to seawater, petroleum products, resists freeze thaw cycles. For cold weather working Parex Epoxy Winter Additive will improve low temperature strength development.

Uses include:

- Machinery base plates.

- Crane rail tracks.

- Bridge Bearings.

- Compressors and pumps.

- Reciprocating machinery.

- High impact loads.

- Space filling and stress transfer

Specification Outline

Grouting shall be carried out using E20 Epoxy Grout as manufactured by Parex Ltd. The product must be stored, handled and used strictly in accordance with the manufacturer’s instructions.

Quality Assurance

Parex Limited has an integrated business management system. This is externally accredited by UK CARES to BS EN ISO 9001:2015, BS EN ISO 14001:2015, BS ISO 45001:2018 and BES 6001.

Instructions For Use

Preparation

Remove laitance and all loose material including dust, oil and grease to achieve a sound substrate. Steel surfaces should be free of mill scale and rust. Surfaces to be grouted should be free of standing water and in a surface dry condition. Formwork must be designed with sufficient hydrostatic head to ensure grout flow into and across the grouting area and should be made grout tight. Apply a silicone based release agent to the formwork surfaces which will effect release after grout has hardened. Alternatively use thick polythene sheet firmly fixed to the formwork.

Mixing

Mixing of Parex E20 Epoxy Grout should be carried out with full packs only. Pour all of the resin and hardener into a clean mixing vessel. Mix with a slow speed drill (200-300rpm) and Mortar Stirrer (MR4) until homogeneous. Slowly add the filler to the mixed resin and hardener. When all the filler has been added, mix for a further two minutes until an even colour is achieved. Try and ensure that air entrainment is kept to a minimum by keeping the mixing head below the surface level of the grout at all times. Larger volumes may be mixed using a forced action mixer such as the Creteangle.

Placing

Allow mixed grout to stand for 5 minutes prior to placing to allow entrained air from mixing to be released. Place grout continuously into the work area from one side only. Where further mixes are required to fill the void, these should be prepared in sequence such that pouring is continuous. Place mixed grout within 30 minutes after start of mixing. Place in nominally parallel gap widths between 8mm and 25mm. Tapered sections may be placed down to a featheredge. For thicker sections use E33, E70 or E140 variants. Do not disturb the grouted section until the grout has hardened. Tools and mixing equipment should be cleaned with Solvent before grout has hardened. Set grout can only be removed mechanically. E20 Epoxy Grout may be placed at temperatures between 5°C and 45°C. For placing outside this range contact the Technical Service Department.

Curing

No special curing is required.

For more information on Parex E20 Epoxy Grout click here